Roots Hummus has done a tremendous job spreading their chickpea-spread to grocery stores across the country. They have a very strong customer base who have helped share their product around the US, but with that level of popularity comes a lot of requests – customers reach out wanting to purchase Roots Hummus but without a grocery store near them that carry the product. While it can be extremely difficult to logistically offer single consumer online purchasing for a single food product, Roots Hummus had a need to reach customers who could not access their product any other way. We were hired to create a solution to this problem and discover a way to make running Roots Hummus e-commerce store a profitable venture.

Problem:

We needed to reach customers who cannot currently access Roots Hummus products through the grocery stores in their area.

This problem has existed for Roots Hummus since their explosion in popularity over the last decade. However, with the immersion of covid-19, it presented a new need for e-commerce. Some people may not be able to go to the grocery store to buy their hummus. Now, Roots has even more customers who could benefit from an e-commerce store. With this extra push, the e-commerce project commenced.

But this is not just a typical e-commerce store – as mentioned, this is a cold-storage food product, making it expensive to ship an already low cost product, shrinking the profit margin, along with various barriers to entry such as cold-storage, fulfillment, special packaging, shipping logistics, and more.

Solution:

- Packaging Logistics

Before we could establish our shipping logistics, we need to know how we will be packaging the product. The weight is extremely important, as the smaller and lighter the product, the cheaper the shipping. However, we also need to be able to fit as many products in the package as we can in order to create a purchase price that allows the company to make profit. We set up meetings with multiple packaging solution companies around the country and locally. We ran tests with these companies to establish what kind of refrigeration, or coolant solution we would use in the packaging to keep the product cold, and how long we could keep the product cold to get longer shipping times and therefore lower shipping rates. We could choose between dry ice, gel packs, ice, or ice packs. Each has their own pros and cons, but dry ice is extremely expensive to ship by air and comes with various regulations and restrictions, which quickly ruled out that possibility. Additionally, we needed to come up with a solution for the liner, which is the cooler-like material inside of the cardboard box we ship in. It was very important to the client that the solution be as sustainable as possible and with the smallest environmental footprint. We tested with each solution and came to the conclusion that we could fit three gel packs for 4-tubs of hummus within a recyclable material liner for close to 72 hours. This gave us the ability to do 2-day shipping, get our product size down as small as possible, and be sustainable. However, all of these packaging solutions come with costs that add up, and our profit margin is shrinking. So now, we need to establish the best shipping rates possible. - Shipping Logistics

Now that we know what our packaging will look like, it’s time to establish shipping rates. As you can imagine, shipping cold-storage products across the country is not cheap. It was our job to figure out a solution that could fit within the profit margin. We scheduled meetings with FedEx, UPS, and Stamps.com (USPS) to present our plan and get pricing options. We had multiple back and forth communications to establish the optimal product weights and heights to establish our DIM Divisor. A DIM divisor is a number set by the freight carrier to represent cubic inches per pound and establish how the pricing model will work. We decided to move forward with an exclusive partnership with UPS, allowing our products to be shipped 2-day ground to almost the entire East coast, and 2-day air to the West coast and central US. This left great rates for the majority of our customers, but expensive rates for those farther out. This leaves a decision on fulfillment. To begin, we plan to fulfill orders in the Roots Hummus facility, but in the future, we could partner with a company on the west coast to assist with fulfillment and therefore create cheaper shipping rates on the west coast by shipping from that fulfillment center. In the meantime, the solution was that this product is exclusive to the consumer, and to start, they will have to pay higher shipping rates to get the product to them across the country and that those rates will be paid by the customer, not within the cost of the product. - Product Logistics

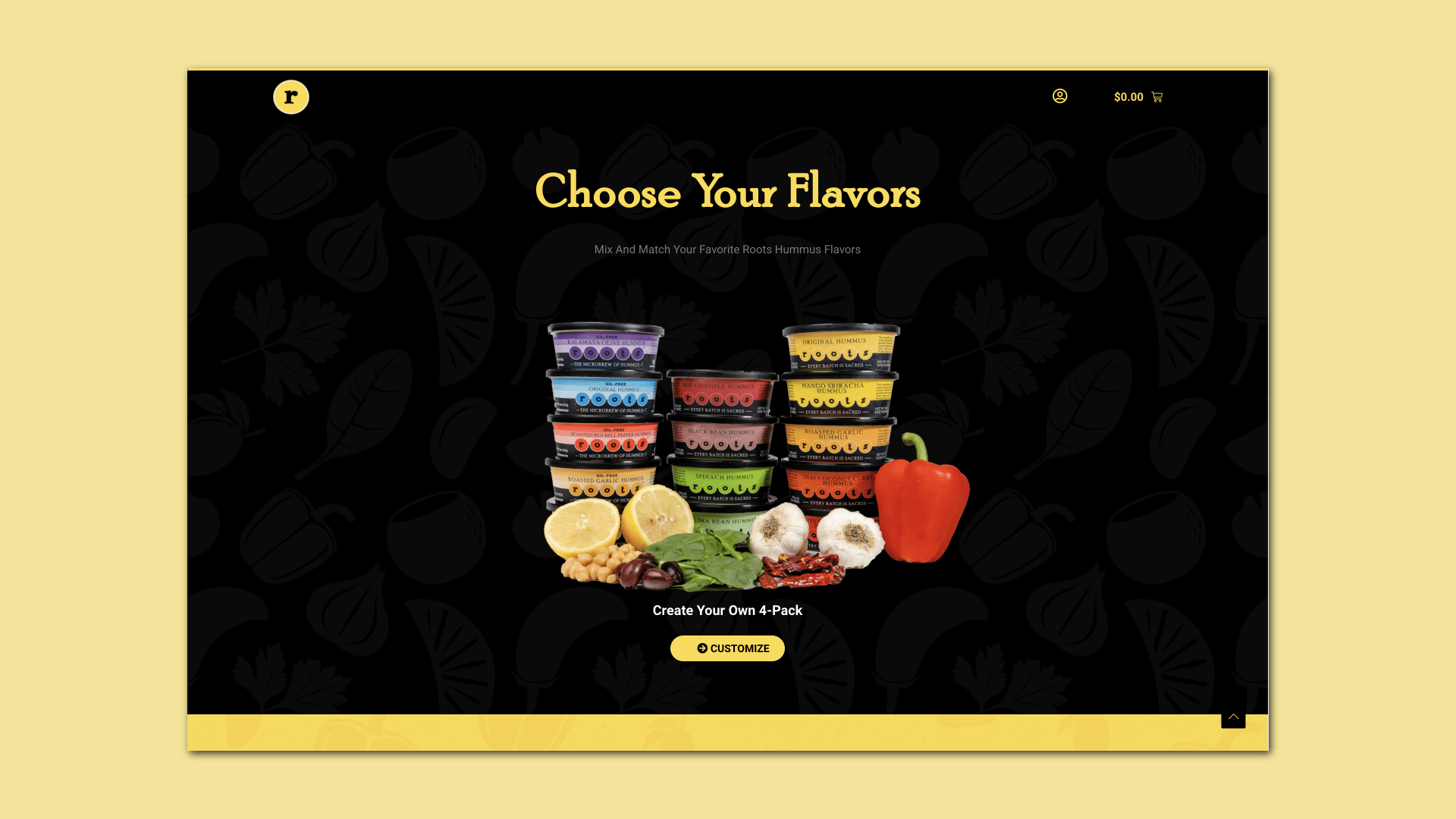

In order to have a positive profit margin, it would not make sense to ship one tub of hummus that the customer pays around $3-4 for one tub. After doing various calculations, we established the optimal number of tubs per order for the company to make profit and for the consumer to consume within expiration date of the product was 4 tubs per order. So we developed a 4-pack size product and designed the e-commerce experience to be a ‘pick your flavors’ ‘mix-and-match’ for your four pack, since many of the customers are ordering online because they cannot find their favorite flavors in stores near them. - Fulfillment Logistics

Again, we met with multiple companies to discuss logistics for fulfillment. We decided to move forward with ShipStation, as they have the most user-friendly back-end that easily migrates with UPS and Woo-Commerce. Once we were set up with ShipStation, our Dolo Digital team met with the Roots Hummus fulfillment team and taught them how to use the software. For now, all orders are being fulfilled from the Asheville warehouse.

As mentioned, in the future it will be beneficial to have a fulfillment center on the opposite side of the nation to give a lower barrier to entry for customers to order the hummus in California. Currently, the shipping cost is too high for most customers to justify ordering online. But once a fulfillment center is established in the West, we can increase marketing spend and orders in California.

Website Store Development

The Roots Hummus website is a WordPress website using WooCommerce to power to the e-commerce features. We wanted the shop website to be on a separate domain to keep it organized, since with the shop there are more users, features and add-ons that can be developed further.

Results:

- Roots now has a new revenue stream for little extra time/cost and minimal overhead

- We were able to successfully create a packaging, product and shipping solution that left room for a profit margin worth executing the project.

- A new Marketing Vehicle – Now, not only can Roots Hummus sell to any customers anywhere in the US, but they can now use digital marketing tactics to target areas that they do not have a large footprint and begin to create brand fans in that area. For instance, if Roots Hummus does not sell to any grocery stores in New Orleans, but we decide there are a lot of hummus eaters in New Orleans, we can run digital ads to increase online sales in New Orleans. Once online sales in New Orleans are high and the amount of customers is high, Roots Hummus can use that date to sell to New Orleans’ grocery stores. Essentially, the e-commerce is a great tool to enter into a new market.